Plastic extrusion

When we talk about plastic extrusion, there are not many people not in the field that knows what the process is about; when we talk about the extrusion machinery, however, people who know what goes on in that department are even fewer.

Plasticol, company located in Samarate, can count on top quality machinery through which we get great finished goods. Our 12 productions lines of rigid, soft and coextruded products let us satisfy each and every single request and order placed by our clients and help us create any sort of item, from sheets to wires, from cables to generic profiles.

The main components of extrusion machinery

Despite the existence of many different extrusion types of machinery available on the market, many are the components that can be found in every model. In fact, the two main differences in the equipment lay in the technology and the kind of mold used (different molds are used to create different products).

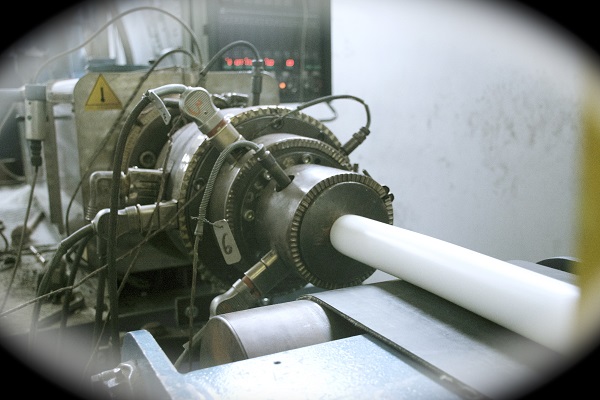

Every machinery that we use in our headquarter has a hopper, for example, from which the plastic granules that we produce fall into the main chamber of the extruder. Another very important piece in this type of equipment is the barrel that contains the resistances that melt the plastic and make it malleable. Other than the resistances, in the barrel we can find also a screw that moves and pushes the melted material towards the last part of the machinery; the screw drive is attached to a motor.

At the end of the barrel, there is a conjunction segment characterized by a decreasing diameter that regulates the plastic flow to the mold. This component changes depending on the type of product requested and it’s the piece that defines the shape and the thickness of the final good. Moreover, accordingly to the final product, the mold can be either completely hollow or equipped with a core; it can even have more than one opening.

Plasticol

Location: Via San Carlo 35

21017- Samarate (VA)

Phone number: (+39) 0331 234 212

FAX: (+39) 0331 235 108

Email: info@plasticol.it