A very requested service

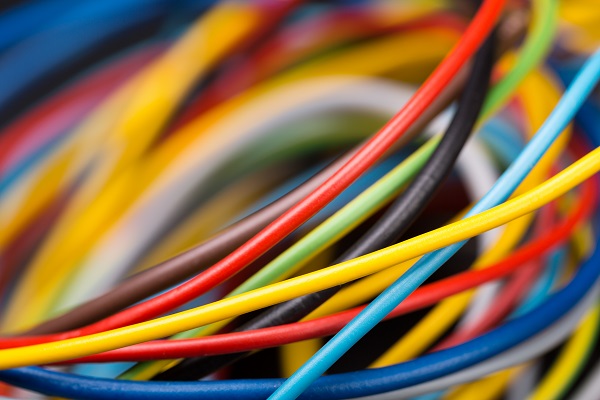

Plasticol, a company located in Samarate, works in the plastic extrusion field. The materials we use in our factory are all created by us, therefore are great quality products; after all, we pay a great amount of attention at every step of the manufacturing process and we put a lot of effort to assure that we create the best materials possible. Plasticol manufactures PVC, ABS, polyurethane, polyethylene, polypropylene, as well as thermoplastic elastomers.

Our clients can count on a great customer assistance experience since each of them gets assigned a personal consultant who helps them to create a product that perfectly matches the clients’ needs.

In addition to the extrusion of pipes, cables, profiles, and sheets, Plasticol offers many other services among which there are the digital printing of the final goods, the production of custom designs and the hot gas welding of plastic products. This last service we just mentioned is extremely useful for those companies that work in hydraulics, the construction field, the automotive sector or if they pave buildings with plastic slabs.

How does the hot gas welding of plastic products work?

We’re sure that everyone knows that plastic melts if heated. Plasticol takes advantage of this particular characteristic to join plastic components, and to do so we use the hot gas welding method. Thanks to very high temperatures and a bit of pressure, the extruded products we create in our factory can be joined indissolubly and hermetically in just a few minutes; our clients can then enjoy sturdy and strong objects that are extremely long lasting.

The welding process doesn’t affect in any way the chemical-physical properties of the materials and there’s no need to add special additives to the plastic in order to weld two extruded products together. Based on which objects we’re working with, the type of welding technique used will be different; Plasticol’s employees’ study which strategy is the best to use in each case so to guarantee to our clients the greatest result possible.

The machinery we use is top quality and help us obtain exceptional results since they combine both the heating up phase and the pressure process. The temperature necessary to get a stable and permanent joint varies from 250°C and 350°C; the material reaches that level of heat thanks to a spurt of hot air. Through the use of this type of equipment, we can join objects of any size.

Once the welded products cool down they can be packed, stored, and shipped to our clients, who are located all over the globe!

Plasticol

Location: Via San Carlo 35

21017- Samarate (VA)

Phone number: (+39) 0331 234 212

FAX: (+39) 0331 235 108

Email: info@plasticol.it